|

AITG PLASTIC MACHINERY CO.,LTD

|

Twin - wall Hollow Plastic Tiles Extrusion Machine For Roofing Sheet

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Twin - wall Hollow Plastic Roofing Tile

Twin - wall Hollow Plastic Roofing Tiles Extrusion Machine For Roofing Sheet

The Twin-wall Hollow Roofing Sheet Extrusion Line is mechanotronics, with the advantages of:

1) high production efficiency;

2) reasonable structure compact;

3) convenient operation and maintenance

4) long use life etc.

Description:

making machine, plastic machine, extrusion, extrusion line, production line, roofing sheet making machine, roof machine, tile machine

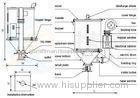

- This Twin-wall hollow roofing sheet production line consists of extruders, extrusion mould, calibration system, haul-off machine, cutter and stacker.

- The extrusion mould adopts the latest co-extrusion technology with very precise design with multi-cavities.

- The shaping mould includes the vacuum calibrating system and special design of cooling runner with excellent cooling effect.

- The surface UV-layer is co-extruded with ASA/PMMA bright color, which is not easy to fade.

Specifications:

|

Main extruder |

SJZS-80+SJ-50 |

SJZS-92+SJ-65 |

|

Width of finished product |

830 mm |

1000 mm |

|

Thickness of finished product |

12mm |

14mm |

|

Drive motor |

55kw+15kw |

110kw+18.5kw |

|

max output |

300kg/h+50 kg/h |

600 kg/h+80kg/h |

Applications:

The Twin-wall hollow roofing sheet making machine is mainly used in the production of plastic twin-wall hollow roofing sheet , which compared with traditional plastic roofing sheet, this twin-wall hollow roofing sheet is better for heat and sound resistance. It is suitable for tropical weather with advantage of anti-corrosion, rust-proof, strong durability, and beautiful appearance, easy and fast installation. Because of the stronger rigidity, the twin-wall hollow roofing sheet is widely used in the factories (including chemical and treatment plant), sports stadium, schools, agriculture industry, marine, warehouse and commercial buildings.

Competitive Advantage:

The extrusion mould adopts the latest co-extrusion technology with very precise design with multi-cavities. The shaping mould includes the vacuum calibrating system and special design of cooling runner with excellent cooling effect.

Extruder mould

Extrusion mould with special designed co-extrusion runner,make the ASA extrusion uniformity and use less material.

Eight roller haul-off machine

The haul-off machine equips with five sets roller,the roller shape is same with the roofing sheet,avoid the products deformation and has smooth traction.